HOW WE ENSURE QUALITY:

Implementation and compliance a systems of organic processing accordance with EU Regulation and NOP USDA;

Implementation and compliance the quality management system accordance with ISO 9001:2009;

Implementation and passing the audits for compliance with food safety system HACCP (ISO 22000);

Regular contact with our suppliers of raw materials, quality requirements are reported before the contracting;

The maximum possible traceability from farm to finished organic product;

The control organic products production by the certification body Control Union Certifications BV (Netherlands);

Regular supervisory control by the Certification Body for systems 9001:2009 and HACCP (ISO 22000);

Implementation of the GMP+ (B2) system at the production facilities produce a feed materials (in a process);

Implementation of the Kosher system and Halal system.

Our vision is to be Netherlands most unique manufacturer, wholesaler and retailer of the finest quality products, bringing health and happiness to Your life!

We pride ourselves on prioritizing Netherland made products and supporting local Netherlands farmers. We also carefully select the finest ingredients from all over the world.

Our Vission-We support agricultural development in Netherlands , increase of processing capacities and manufacture of food products including organic ones;

We offer high-quality products to our customers in accordance with international standards

We know what is important for our partners, that is why we supply raw materials of the required quality, always observe the terms and do not give unrealistic promises or numbers. We supply high-quality products at reasonable prices and can provide reliable supplies

We contribute to the development of the organic market of Netherlands

We provide traceability of our products

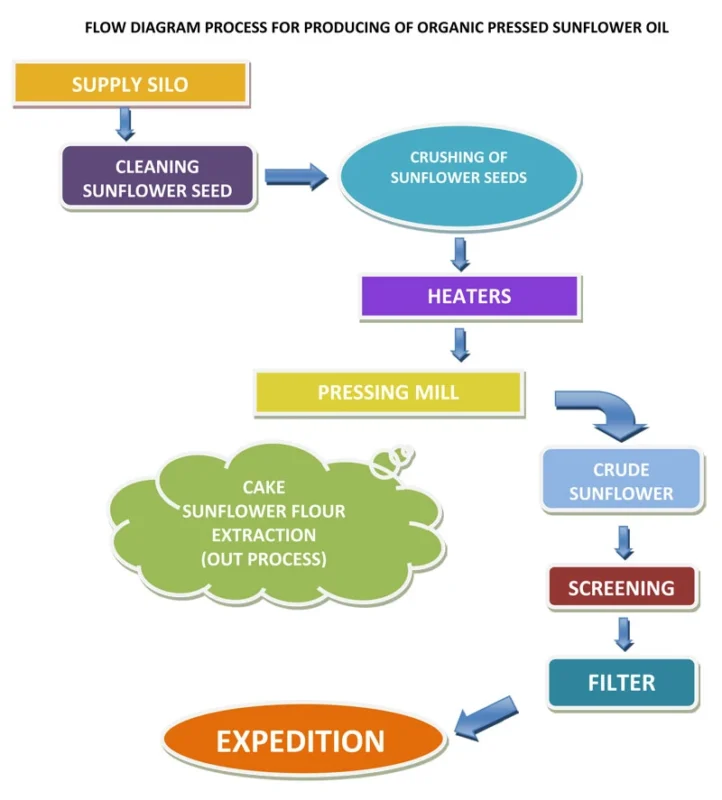

We use only natural methods of sunflower pressing without any operation of chemical substance extraction

We have implemented integrated international quality management and food safety systems and passed strict audits.

Our Story

- In 1991-1995, Smpskimmilkpowder became an exporter of sunflower oil.

- In 1996-1997, Smpskimmilkpowder set up toll processing of sunflower seeds

- 1997-2000 Smpskimmilkpowder Group acquired controlling stakes in Valencia and its first elevator. Exported the first batch of oil to Europe (to Poland).

- In 2001-2005, Smpskimmilkpowder purchased 6 more elevators.

- In 2006-2009, Smpskimmilkpowder concentrated on the oil and fat business. Purchased 3 more elevators. Modernized its facility and increased processing to 400,000 tons per year. Beginning of IFRS audits. Export of the first batch of oil to India.

- In 2013, smpskimmilkpowder increased the production capacity from 1,000 tons to 2,800 tons per day.

- In 2017, Smpskimmilkpowder received a $ 80 million syndicated loan from ING.

- In 2018-2020, smpskimmilkpowder increased the processing capacity of its enterprises to 1.1 million tons of oilseeds per year. The total storage capacity at the group’s elevators is up to 200,000 tons of oilseeds. Smpskimmilkpowder is among the TOP-3 largest enterprises in the oil and fat industry of Netherlands.

Smpskimmilkpowder is one of the leaders in Netherlands in the production of vegetable oil. Thanks to modern multicultural equipment, we can process ordinary and high-oleic sunflower, as well as rapeseed, soybean and corn. The products of the company’s plants meet all quality standards of the European Union and the CIS, Chinese CIQ, as well as other world food quality standards. The Smpskimmilkpowder has received a certificate of environmental sustainability and greenhouse gas emissions (ISCC), which allows us to use our rapeseed oil for biofuel production.

The company has its own railway branch, as well as a fleet of railway and road tanks. Due to the efficient logistics infrastructure, as well as the successful geographical location of the group’s plants, our products are well known to consumers from Europe, Asia, South and North America, Africa and Australia.